Operation name: Integration of high performance polymer components in robotic applications

Leading partner: Podkrižnik d.o.o.

Project partners: Budapest Faculty of Mechanical Engineering, department of Polymer Engineering, X-Plast Kft.

Duration of the operation: from 1. 9. 2022 to 31. 8. 2025

Description:

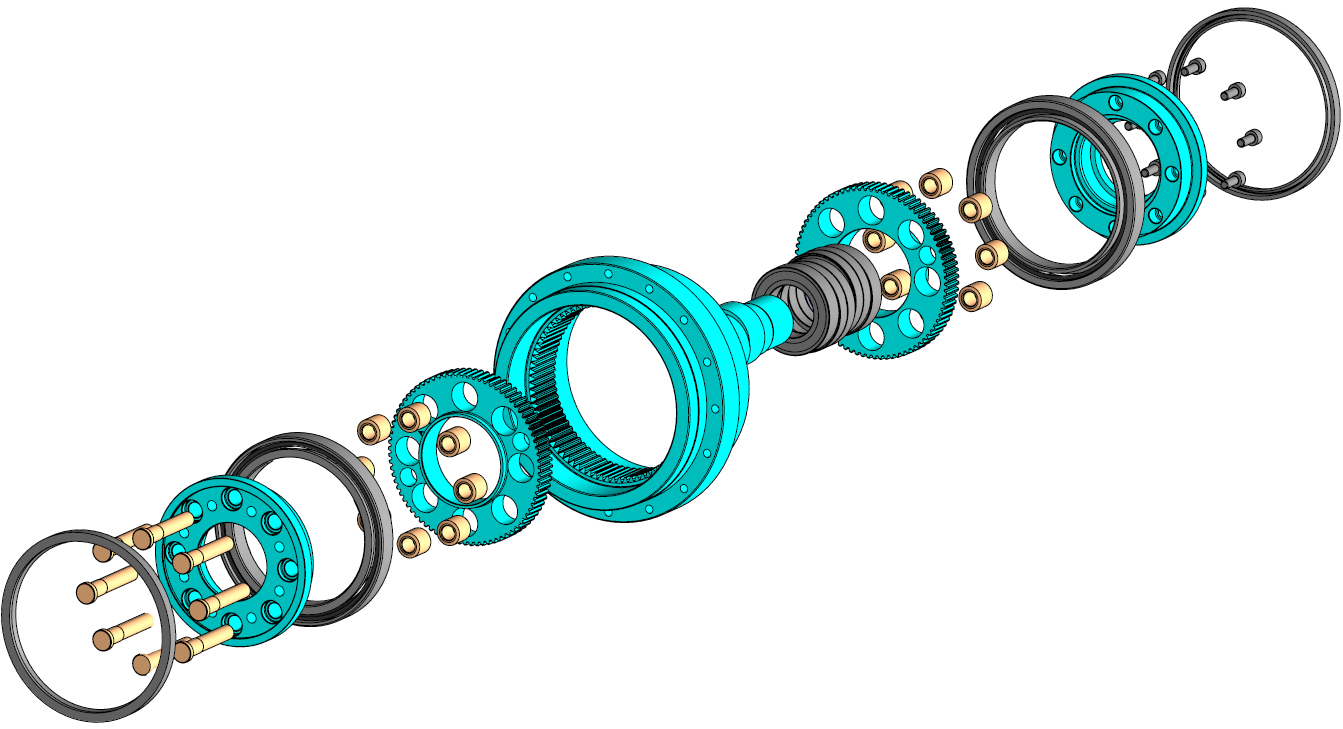

In the robotics market, due to the optimization of production times and better accuracy and reliability, there is a tendency to increase the number of robots used in production. As their number increases, so does the spectrum of their use. In parallel with precision, the mass of robotic drive systems is also extremely important in certain application segments. This project is about upgrading the SGU drive, which is a robotic ultra-precision drive system, developed by the company Podkrižnik d.o.o. (also as part of past projects such as Gostop, SGU…). Existing product shows potential in reducing mass. With the knowledge we have and the involvement of a scientific institution, we can make a significant breakthrough in the mentioned market area.

Project value: 633.776,75 EUR

Co-financing value: 177.303,84 EUR

Goals of the operation:

The main goal of the project is to develop a new product „Gear drive system for high precision and demanding applications with integrated advanced polymer components". It is a hybrid – steel and polymer robotic drive system, which can be found in industrial robots (typically 3 to 6 pieces/robot). The drive will combine the advantages of both basic materials, i.e. low own weight with sufficient load capacity and positioning accuracy. The goal is to reduce mass for about 15-25 %, while keeping the best possible performance of the drive system.

The investment is co-financed by the Republic of Slovenia as part of the Program of Financial Incentives of the Ministry of Higher Education, Science and Innovation 2015-2020, State Aid Scheme „Program of Financial Incentives MGRT – RRI“.

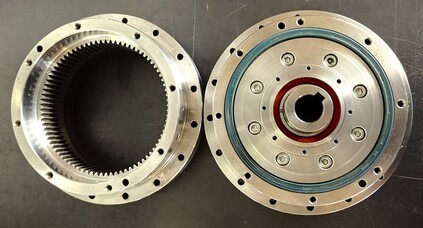

The starting point of the project was the original metal version of robotic ultra-precision drive, developed by the company Podkrižnik d.o.o. (also as part of past projects such as Gostop, SGU…). The drive operates according to the principle of eccentric cycloidal drive systems. It is mostly made of steel, but within the framework of this project, we want to make a hybrid version that will also contain polymer material. The goal is to reduce mass for about 15-25 %, while keeping the best possible performance of the drive system.

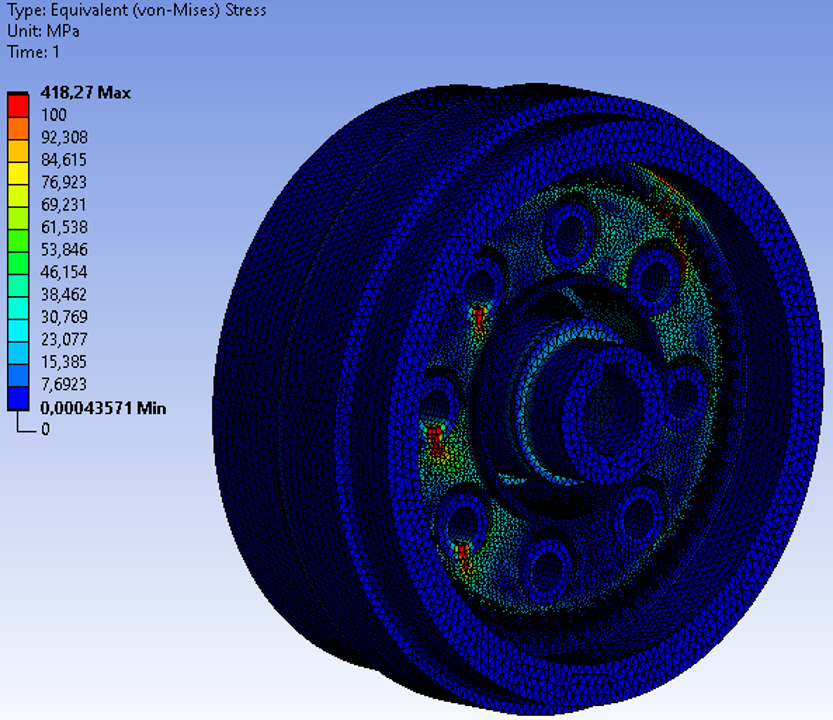

We created a numerical simulation (FEM analysis) of the entire original drive, which we slightly simplified for this purpose. Simplification did not affect the functions of the drive unit, but we only removed geometrically irregular shapes (e.g. technological details). Most of the housing showed low equivalent stresses, which confirms it as a right component for hybridization, while the other components are subjected to significantly higher stresses and are thus less suitable for material replacement.

In the next step the simulations of the housing variants were carried out iteratively, which means that we repeated each analysis several times, and between each iteration we changed the simulation conditions (e.g. numerical mesh density, type of selected numerical element, etc.). The simulation results of the final optimized geometry brought us to the conclusion, that stress values are within the permitted range, and we could confirm the structural adequacy of the design.

Also some topological analysis were performed to create the optimal design of hybrid housing.

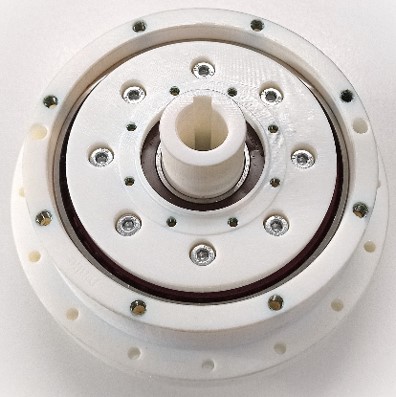

Three versions of the prototype drives were assembled, in which most of the components were produced using 3D printing technology of plastic materials. First prototype was made of ABS CF10 material, second of ASA Black material and third of VeroPureWhite material. When assembling, we paid attention to the appropriate assembly process, to avoid damage to the bearings, components etc. Before assembling, all components were measured (measurement equipment such as 3D CMM machines for gear measurements were included). Mass comparison between the original drive (metal components) and the 3D printed drive (plastic components) showed, that we reached approx. 71,4 % mass reduction.

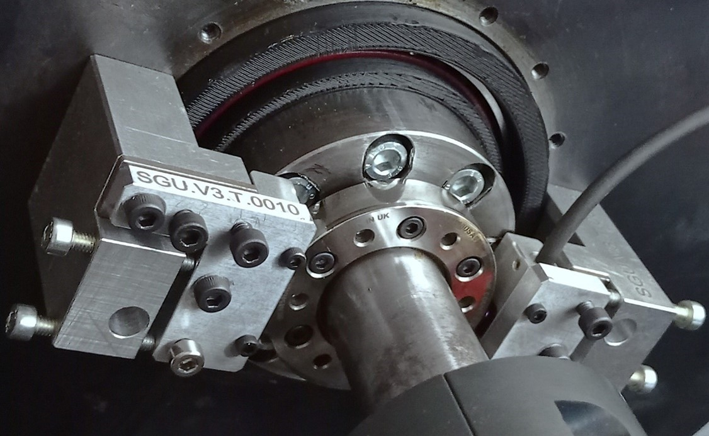

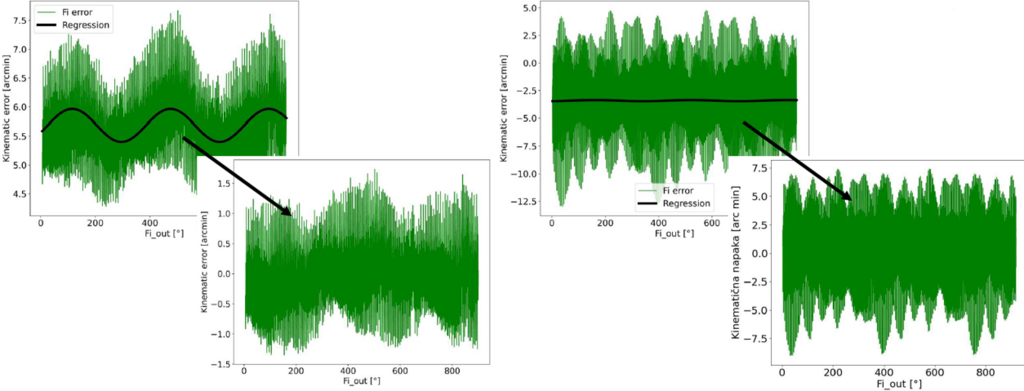

The company Podkrižnik d.o.o. has custom testing device for testing robotic drive systems, where vaious types of tests can be performed. In this case, three types of tests were performed: measurement of kinematic error, stiffness and clearance and lifetime test. A comparison of test results between the metal and 3D printed plastic prototype drives showed that there are considerable differences, especially when analyzing stiffness and lifetime. In addition to the lower stiffness of the 3D printed plastic materials, the precision of manufacturing individual components also played an important role in the result, as the technology used offers approximately a factor of 100 worse precision than the technologies used in the metal drive.

We used Dewesoft equipment for data acquisition (Dewe-43A DAQ modules). For torque and position measurements, we used Kistler torque sensors and Renishaw precise encoder rings with reading heads. For vibrations and temperature measurements we used Dytran accelerometers and K type thermocouples. The collected data were then processed with the help of custom written programs in the Python programming language. A comparative analysis of the results between the original metal gear and the prototype plastic gears was performed.

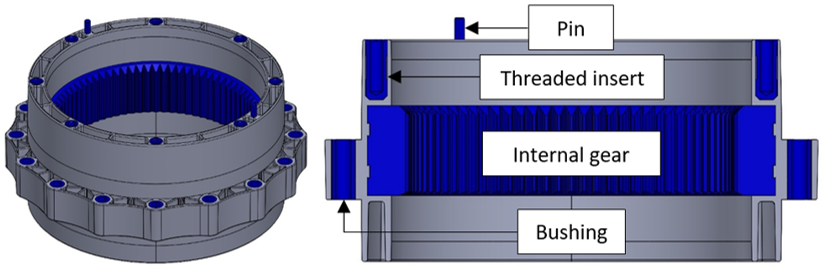

After analyzing the results, we made a conclusion, that the hybrid housing would be the most optimal solution for semi-serial production. In this case, the more loaded parts, such as gear ring, bushings, threaded inserts, will remain metal, while the rest of the housing will be made of plastic material.

In the continuation of the project, the production of these prototype hybrid housings will be completed. They will be then installed in semi-serial drives and tested in accordance with the presented procedure.

The following articles were published as part of the project: